For the past 2 weeks I have been making various simple styrene models, practising how to cut styrene squarely. It was a good learning experience for me and that brings me to consider buying a mitre cutter. I have a couple of scale modelling projects lined-up for a long winter season.

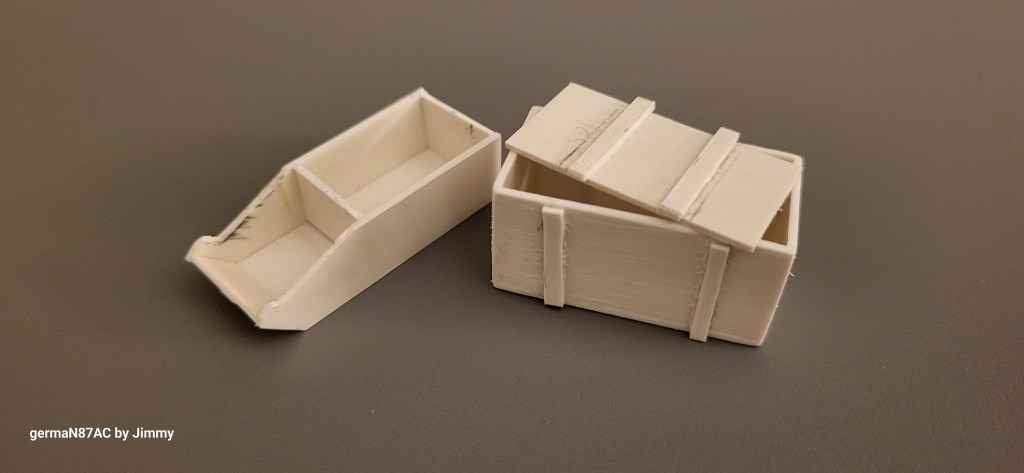

On left front cab of Cottbus Park Railway ICE, one right a wooden crate based on AK Learning Series 15 instructions.

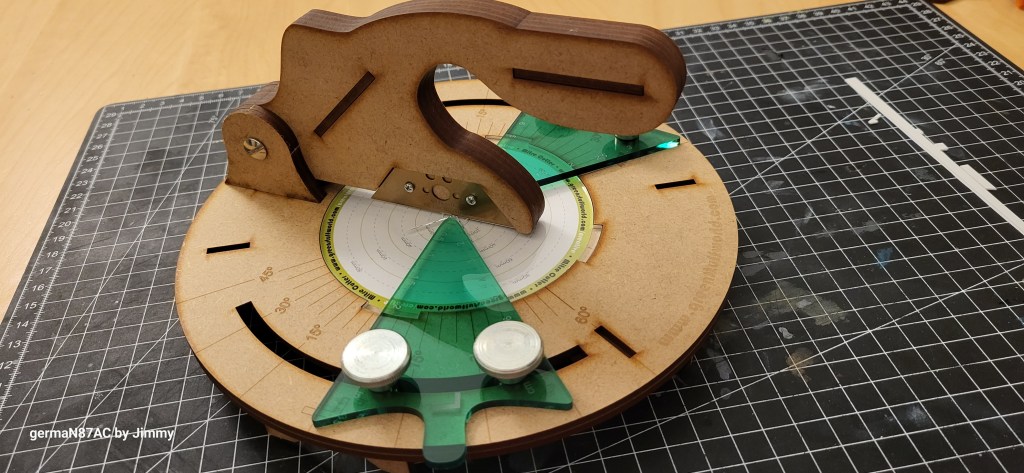

In the market there are only a handful of mitre cutter. RP Toolz Precision Mitre Cutter is one of them but at a price of averagely more than 100 Euro (at time of this post). I thought deeply whether I should invest in RP Toolz or find a cheaper alternative. In the end, I settled for an afforable one as I am just starting in the scale modelling hobby; thus, I chose Green Stuff World Mitre Cutter.

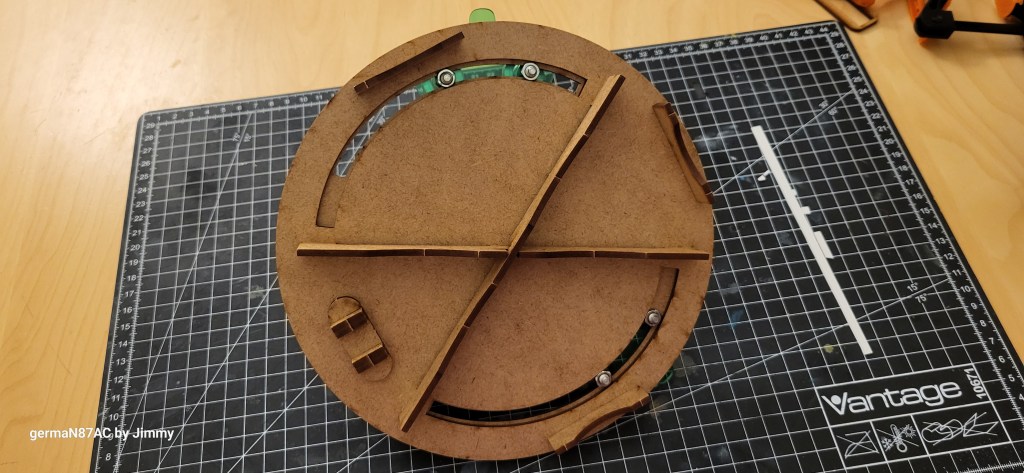

GSW mitre cutter consists of self-assembled laser cut components made from thin MDF boards. The handle for the blade is made from 4 pieces glued together. The side base supporting the handle is made from 2 pieces on each side; thus, ensuring a sturdy handling.

The base is also well-supported to ensure stability when cutting. As you can see, I tried cutting a piece of 1mm thick styrene stripe into various small pieces and at various angles. Two arrowed-shaped green guides, one on each side, guide the styrene piece when cutting. Each side can mode between +45° to -60° i.e. depending on how you position your styrene, you can cut up to 60° angle. Thus, if you want to cut 130°, you will have to position your piece at 40° (130° – 90°)

I am looking forward to my scale modelling projects.