Locomotives and wagons on exhibit needs a stable foundation to rest. In fact, Loewenherz has at least 3 plinths for permanent and revolving exhibits.

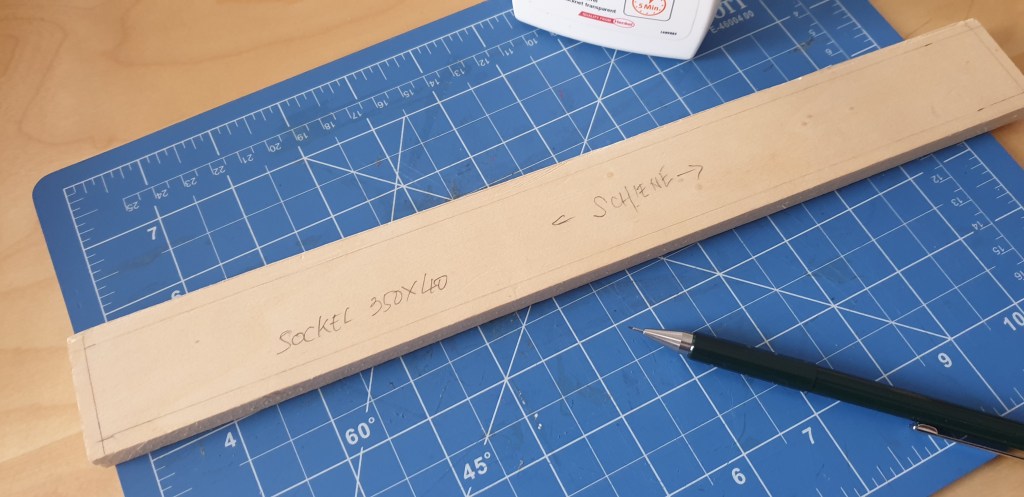

I experimented with 10mm plywood and 3mm cork as materials for various forms of plinths. Each material has its own merits – weight, stiffness, ease to mold etc. as well as look-and-feel. I wanted to experiment.

Material: 10mm Plywood vs 3mm Cork

In terms of hardness, no doubt plywood fulfilled its purpose. You need a wood saw and other tools to cut into shape. Cork is easy to cut with a paper cutter and shape but it is brittle. Adding a few layers of cork will give you the stiffness you want.

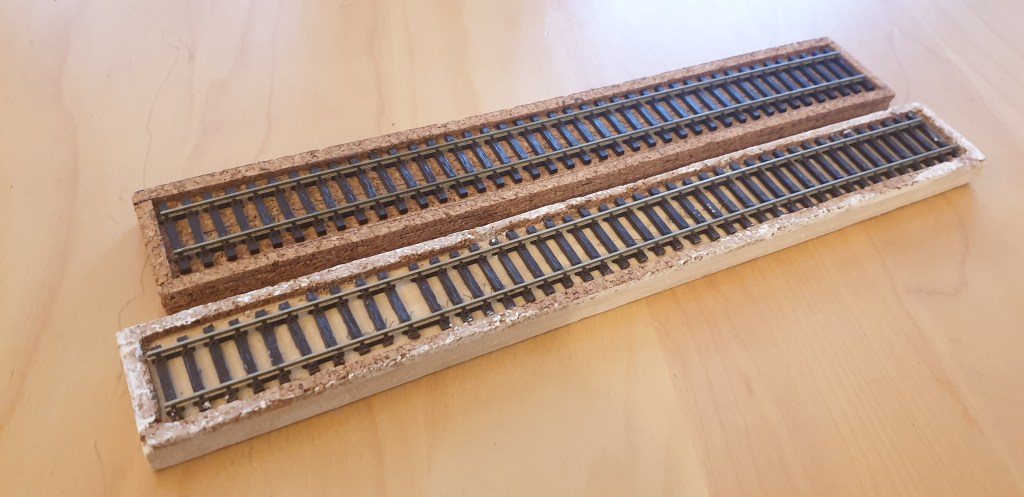

Optic: Plywood vs Cork Unweathered

I used Molto putty filling on plywood to create concrete surface and texture. For cork, I will leave it as is since it should be stone plinth. The grainy surface of cork looks nice with H0 model on it and figures at sides.

Overall Impression

I am pleased with the overall look and feel of both plywood and cork plinths and weathered them to give an aged look . After all, these plinths should be at least 40 years old and always under the elements.

What do you think? Give me your comments below.

One thought on “Building H0 Plinths for Exhibitions”