Disclaimer: This independent review is based on my personal purchase and experience. I am in no way associated with the seller other than this arm-length commercial transaction.

Update 27.11.21: I have successfully ran Märklin BR 53 0002 on KPF-Zeller rolling test stand, powered and controlled by z21 digital control center and app. This post has been updated accordingly.

In Part 1 review last week, I covered static tests i.e. using the rolling test stand as a display. The overall results are impressive. I believe KPF-Zeller exclusive edition is the only one in the market with underside lighting.

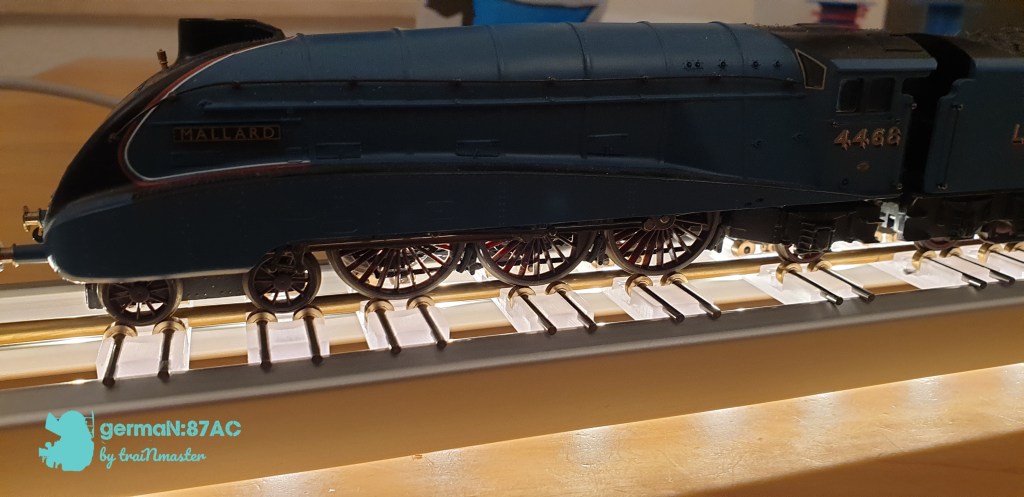

This weekend (14.11.21) I have conducted dynamic running tests on my HO-scale locomotives namely Hornby LNER Mallard 4468 (OO-scale), Piko BR 185 and Atlas Amtrak California Dash 8-32BWH; these are DC (direct current) analog engines.

Two weekends later (27.11.21), I connected my white z21 digital control center (changed the setting to read both DCC and MM) and ran my Märklin BR 53 0002, which has a built-in Märklin Motorola (MM) decoder. Märklin models run on AC (alternating current).

I applied two hypotheses in my dynamic tests:

- Whether the weight of the engine (and if with tender) have any influence on the speed test.

- Whether the engine remaining on the test track at different speeds.

Here are the test results:

| Model | Weight | Speed Performance |

|---|---|---|

| Märklin BR 53 (AC) | 752g (with tender) | On my z21 app, I started with 1km/h and the back driving wheels started to run and as I accelerated to up 40km/h, the wheels ran well without jumping off the trolleys. |

| Piko BR 185 (DC) | 510g | Above Speed 50, wheels moved and ran smoothly without jumping off the trolleys. |

| Hornby Mallard (DC) | 404g (with tender) | The engine did not pick up any electricity; thus, the driving wheels did not run. |

| 179g (tender only) | The tender picked electricity and run well at Speed 100, 150 and 200 without jumping off trolleys. | |

| Atlas Dash 8 (DC) | 478g | The engine moved only at Speed 150 but slowly and at Speed 200 the wheels, either front or back bogie, will jump off trolleys after ca. 20 seconds (see video) |

From the tests, it does somehow show that the weight of the engine played some role in ensuring that it stays on the trolleys especially at highest speed (BR 185 and BR 53 vs Dash 8). I could see how BR 185 and BR 53 was able to hold on whereas on Dash 8 either front or back, but surprisingly not both bogies will slide off and leave the trolley. This, however, did not happen on LNER tender, despite weighting only 179g.

In my opinion, the weight of an engine could play a part in ensuring that the wheels stay in contact with the trolleys; thus, putting its weight on the contact bars and the aluminum bars that ultimately carry the electricity to the wheels. Here are the videos on all 4 tests:

Conclusion from Part 1 and 2 Reviews

After looking at a few rolling test stands (comments and reviews (fora, YouTube videos from other users), I decided to purchase for KPF-Zeller Rollerprüfstand (rolling test stand)

- I like the underside lighting with translucent trolleys for static display. As you can see from my photos in Part 1 review, the translucent trolleys do not hinder the underside lighting. In fact, they helps to dissipate and enhance the lighting throughout the length of the stand.

- You can buy any number of trolleys and position them anywhere you want on the stand. From Bo’Bo’ to (1’C)D axle arrangements, you can position your engine anywhere you want. It does not have to be in the middle.

- The power supply for the lighting comes with 3.47m cord. Sufficient for some display cabinets or if you want display on table.

- It supports 2- and 3-rail power system. I could use it for my DC/DCC engines as well as AC engines.

Other points for you to consider (note: these may not necessarily be negative points)

- The small contact surface between tiny trolley wheels and your engine wheels could be a problem if you run your engine in higher speed. It was a problem on my Dash 8 but not on my BR 185 and BR 53. So, I do not think this is a problem with the stand but rather the model. Nonetheless, I listed it as a possible con to take note.

- The aluminum stand without trolleys is relatively bulky (L 555mm x W 70mm x H 30mm) and weighs 487g. Each translucent trolley adds 8g. So, my stand weighs in total 591g.

Below are comparisons of rolling test stands from various manufacturers:

| HO-scale Stand | Dimension (L/W/H) in mm | Weight (Net) | Power System |

|---|---|---|---|

| KPF-Zeller (Exclusive) | 555/70/30 | 551g | AC and DC |

| RailStand (EZ5201) | 520/40/28 | 560g | AC and DC |

| Märklin (78151) | 520/42/30 | 762g (?) | AC only |

| Hornby (R8211) | 365/80/50 | 322g | DC only |

I am happy with my KPF-Zeller stand and will bring it with me whenever I want to show off my models.